“SURE” BRAND WIRE WOUND RESISTOR - SSA SERIES

SILICON COATED AXIAL LEAD TYPE - Professional Grade

Features:

“SURE” BRAND WIRE WOUND RESISTOR - SSA SERIES

SILICON COATED AXIAL LEAD TYPE - Professional Grade

Features:

General Specifications:

DESCRIPTION

SSA

01

SSA

02

SSA

2.5

SSA

04

SSA

06

SSA

09

SSA

12

SSA

15

SSA

20

Resistance (1) range , Series

And tolerance (2)

± 10 %

± 5 %

E24 Series

0.01 Ω - 0.05 Ω

0.06 Ω - 100 KΩ

Rated dissipation at T amb = 70 °C

1 W

2 W

2.5 W

4 W

6 W

9 W

12 W

15 W

20 W

Temperature coefficient. (3)

R < 10 Ω: 0 to +600ppm/°C

R ≥ 10Ω: - 80 to +140ppm/°C

Operating temperature

- 40 °C to + 200 °C

Basic specification

IEC60 115-1

Limiting voltage

√ (Pn × R)

Stability D R/Rmax after:

Load

Climate tests

Resistance to soldering heat

Short time overload

± 5.0% + 0.1Ω

± 1.0% + 0.05Ω

± 0.5% + 0.05Ω

±2.0% + 0.1Ω

(1) Special resistive values available on request

(2) Tolerances, 0.5, 1, 3 and 10% available on request

(3) Temperature coefficient, 30, 50 and 90ppm/°C, available on request

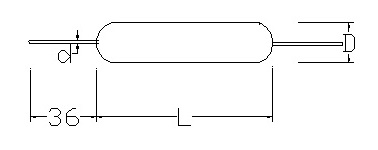

Mechanical Data:

Table 1. Mechanical data

PRODUCT

L

D

d

SSA01

12.0 ± 1.5

4.5 ± 0.5

0.80 ± 0.03

SSA02

14.0 ± 1.5

5.5 ± 0.5

0.80 ± 0.03

SSA2.5

16.0 ± 1.5

5.5 ± 0.5

0.80 ± 0.03

SSA04

18.0 ± 1.5

6.5 ± 0.5

0.80 ± 0.03

SSA06

26.0 ± 1.5

7.5 ± 0.5

0.80 ± 0.03

SSA09

34.0 ± 1.5

8.5 ± 0.5

0.80 ± 0.03

SSA12

54.0 ± 1.5

7.5 ± 0.5

0.80 ± 0.03

SSA15

54.0 ± 1.5

8.5 ± 0.5

0.80 ± 0.03

SSA20

67.0 ± 1.5

9.5 ± 0.5

0.80 ± 0.03

OPTIONS AVAILABLE:

Construction:

SSA: The resistor element is a resistive wire, which is wound, in a single layer, on a ceramic rod. Metal caps are pressed over the ends of the rod. The ends of the resistive wire and the leads are connected to the caps by welding. Tinned copper clad iron leads with poor heat conductivity are employed permitting the use of relatively short leads to obtain stable mounting without overheating. The resistor is coated with green silicon cement which is non-flammable, will not drip even at high overloads and is resistant to most commonly used cleaning solvents

Electrical Characteristics

DERATING: The power that the resistor can dissipate depends on the operating temperature.

Maximum dissipation (Pmax) in percentage of rated as a function of ambient temperature (Tamb)

Test and Requirements

Essentially all tests are carried out in accordance to the schedule of IEC publications 60115–1, category 40/200/56 (rated temperature range -40 to +200 °C; damp heat, long term, 56 days and along the lines of IEC publications 60068-2); “Recommended basic climatic and mechanical robustness testing procedure for electronic components” and under standard atmosphere conditions according to IEC 60068-1 subclause 5.3, unless otherwise specified.

In some instances deviations from IEC applications were necessary for our method specified.

Table 8. Test and requirements

TEST

PROCEDURE

REQUIREMENTS

Temperature coefficient

Between - 40 °C and + 200 °C:

R < 10 Ω

R ≥ 10 Ω

0 to 600 ppm/°C

- 80 to +140 ppm / °C

Rated Load

Rated wattage for 30 minutes ±(1% + 0.05W) Short time overload

2.5 times the rated wattage for 5 sec

ΔR/Rmax ±2% +0.1

Insulation Resistance 500 V DC 10MΩ Robustness of

terminations:

Tensile all samples

Bending half number of

samples

Torsion other half

number of samples

Load 10 N; 10 s

Load 5 N; 4 x 90°

2 x 180° in opposite

directions

No visual damage

ΔR/Rmax ±0.5% +0.05

Solderability

(after ageing)

16 h at 155 °C; leads immersed in flux 600, leads immersed 2 mm for 2 ± 0.5 s in a solder bath at 235 ±5 °C

Good tinning;

(≥95% covered)

No Visible Damage

Resistance to

soldering heat

Thermal shock: 3 s;

10 °C; 2.5 mm from body

ΔR/Rmax ±0.5% + 0.05

Rapid change of

temperature

30 minutes at - 40°C and 30 minutes at + 200°C; 5 cycle

No visible damage

ΔR/Rmax ±1% + 0.05

Vibration

Frequency 10 to 500 Hz

(1 to 7W) and 10 to 55 Hz

(10 to 20W),displacement

0.75 mm or acceleration 10 g, three directions;

total 6 h (3x2 h)

No visible damage

ΔR/Rmax ±0.5% + 0.05

Incombustibility 6 times the Rated wattage for 5 minutes Not flammable

| HOME | | PRODUCT RANGE | | PRODUCT PHOTOS | | CONTACT US |

| QUOTATION FORM | | CUSTOMER PROFILE | | COMPANY PROFILE |