“SURE” BRAND WIRE WOUND RESISTORS - SSH

SILICON COATED SPACE HEATER RESISTORS

SPECIALLY DEVELOPED TO MEET EUROPEAN STANDARD

SPACE HEATER:

CONSTRUCTION :-

FORMER :- High quality ceramic former imperious to moisture penetration

and exceptional ability to withstand

thermal shock.

RESISTANCE WIRE :- High quality iron free nickel chromium and copper

nickel wires are space wounds on

former and the ends are spot welded to the terminal.

SILICON COATING :- The composition and method of application of

the silicon coating, Exclusively developed

and employed, is the real secret behind the outstanding performance of

‘SURE’ Heater Resistor under most

severe and climatic conditions.

TERMINAL :- Snap on terminals specially designed to meet global

requirement of the best grip easily.

MOUNTING BRACKET :- The Heater Resistor is provided with powder

coated ‘L’ type mounting bracket with

shock absorbing material between porcelain and metal bracket.

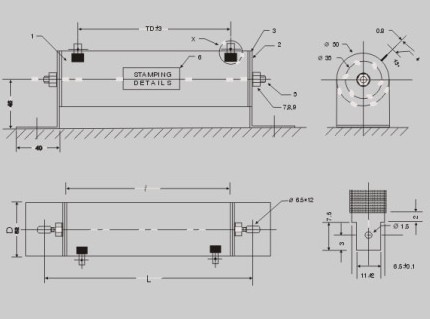

Mechanical Data:

All Dimensions are in mm

Watt |

TD |

l |

L |

100 |

140 |

170 |

200 |

150 |

220 |

250 |

290 |

200 |

270 |

300 |

340 |

250 |

345 |

375 |

415 |

300 |

420 |

450 |

490 |

ELECTRICAL SPECIFICATION

- Standard Tolerance :- +5%.

- Dielectric Strength :- 1000 V. A. C.

- Insulation :- 2.5 KV for 1 minute.

- Megger Value :- Min 100 M with 1000 V megger when tested individually.

- Power Derating

:- Derated Linearly to Zero at 250oC.from normal power rating

at 25oC subject to

temperature limitation of 200oC. - Voltage Co-Efficient :- The resistance value is independent of applied Voltage.

- Stability R

:- < 3% after 2000 hours load test.

< 5% after 56 days climatic and damp heat test.

< 1% after 3 years Shelf Life - Temperature Co-Efficient of Resistance :- <100 PPM/ o C.

SALIENT FEATURES:

- Meet the international standards.

- Mechanically robust.

- Very very long life span.

- Product is guaranteed for two years.

- Constant in ohm value.

- Low PPM for constant heat generation.

- Withstand the most severe condition of humidity.

- Passed the 56 days environment test at ERDA - Baroda.

- Passed the type test at ERTL-Mumbai

as per IEC.

| HOME | | PRODUCT RANGE | | PRODUCT PHOTOS | | CONTACT US |

| QUOTATION FORM | | CUSTOMER PROFILE | | COMPANY PROFILE |